1

2

3

4

5

6

7

8

9

10

11

12

13

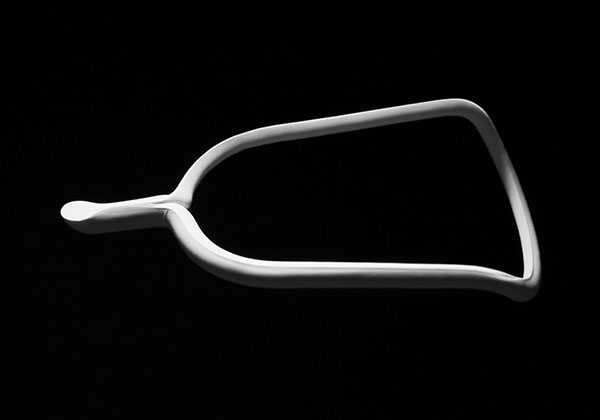

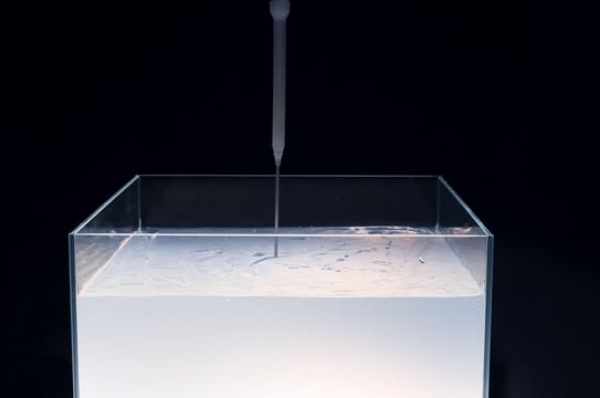

Self-Assembly Lab + Christophe Guberan + Steelcase

In collaboration with Steelcase, we are presenting a new experimental process called Rapid Liquid Printing, a breakthrough 3D printing technology. Rapid Liquid Printing physically draws in 3D space within a gel suspension, and enables the creation of large scale, customized products made of real-world materials. Compared with other techniques we believe this is the first development to combine industrial materials with extremely fast print speeds in a precisely controlled process to yield large-scale products.

3D printing hasn’t taken off as a mainstream manufacturing process for three main reasons: 1) it’s too slow compared to conventional processes like injection molding, casting, milling, etc. 2) it’s limited by scale – although it’s good for creating small components, it’s not possible to produce large scale objects 3) the materials are typically low-quality compared to industrial materials. Rapid Liquid Printing addresses all of these limitations: it is incredibly fast (producing structures in a matter of minutes), designed for large scale products (you can print an entire piece of furniture) and uses real-world, industrial-grade materials.

Self-Assembly Lab Team: Kate Hajash, Bjorn Sparrman, Mattis Koh, Schendy Kernizan, Jared Laucks & Skylar Tibbits

In collaboration with Christophe Guberan

Steelcase Team: Yuka Hiyoshi, Rob Poel, Markus McKenna, Paul Noll, Sharon Tracy, Edward Vander Bilt, Chris Norman & Charlie Forslund